Introduction

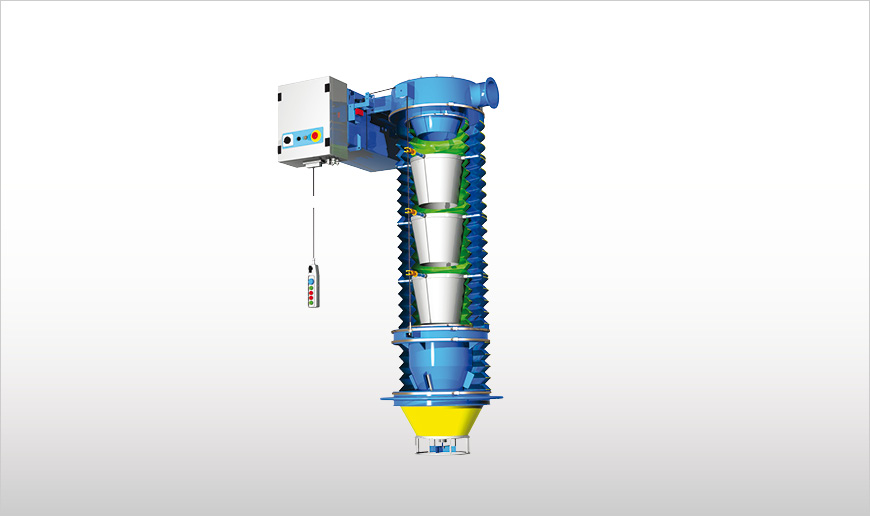

ZG Loading Spouts are ideal for efficient loading of dry, dusty bulk solids into enclosed trucks, railcars and semi-tanker. A solid connection to a centralised filter unit ensures dust-free operation.

Flexible neoprene chute covered with Hypalon makes the bellows weather-proof, highly abrasion and temperature-resistant and durable

Reverse cone with inside level control indicates when tanker is full, gradually raises loading bellows improving material distribution inside the tanker

Two lifting cables outside material flow

Technical Specs

Description

ZG Loading spouts are used for efficient, dust-controlled loading of dry, dusty bulk solids into tankers. The spouts are provided with inner tapered cones to contain the flow of material and an outer double spouts to provide for dust removal.

At the lower end of the Loading spouts, a SINT engineering polymer-coated cone with special sealing properties is provided for connection to the tanker.

Function

First the Loading spouts is lowered from stand-by position towards the inlet spout of the tanker. As soon as the spouts outlet cone settles on the inlet spout of the tanker, the slack cable switch mounted outside the transmission box stops lowering of the spouts. The limit switch inside the transmission box stops both full extension and contraction of the spouts. Material loading starts by opening the silo outlet valve.

During filling of the tanker, the polymer coating of the outlet cone acts as a perfect dust seal. The slack cable switch activates further extension of the spouts as the tanker lowers under the increasing weight of the material. A level control device installed in the centre of the outlet cone signals maximum material level in the tanker compartment and orders immediate closing of the silo outlet valve. Contraction of the spouts back to stand-by position starts after a delay of approximately ten seconds in order to allow the external filter to evacuate the remaining dust. Once the spouts is fully contracted, the cable limit switch inside the transmission box stops operation.

Features

- Inlet diameter: ZG = 300 mm (12 in); ZJ = 400 mm (16 in)

- Maximum throughput rate: ZG = 250 m3/h (147 cfm); ZJ = 440 m3/h (260 cfm)

- Operating temperature: -40 ~ 150 °C (-40 ~ 300 °F)

- Connecting flange for centralised dust suction

Benefits

- Flexible chute in neoprene covered with Hypalon® makes the spouts weather-proof, highly abrasion and temperature-resistant and durable

- Reverse cone with inside level control indicates when tanker is full, gradually raises loading spouts improving material distribution inside the tanker

- Two lifting cables outside the material flow raise and lower the loading spouts without cable wear due to material friction and obstruction to material flow

Options

- ATEX-version available

- Various chute and fabrication materials available according to material handled

- Motor-driven or with handle winch

- Control panel with remote control

- Available with different types of level indicators

- Outlet vibrator

- Anti-spillage device which acts as a dustproof stopper as Loading Spout is being raised