No data found

Granulation in the Ferrous Metallurgy Industry - Coke and Coal Residues

8/26/2020

|

Promotion

Background

To produce steel, it is necessary to use raw materials containing carbon, such as mineral coal, vegetable coal, petroleum coke and so on. Because the raw material particles used are larger than 4-5 millimeters, great quantities of powder residue are generated. Without having a specific use, the residue is “stored” or deposited in industrial landfills, inappropriate or illegal sites, seriously compromising the environment.

Objective

These residues are transformed from powder to granulates, ball briquettes or agglomerates with sufficient mechanical strength and sized for re-use in the iron-making process. To be economically viable, the industrial process must be low in cost.

Technical Verification

A detailed study must be completed to verify the possibility of coke, petroleum, mineral coal or vegetable coal dust transformation. Research was conducted on three conformation procedures:

1. Granulation

The residue (coke powder) was homogenized in WAM equipment with water and binders until obtaining granules larger than 4 mm. Following granulation, the material was dried at 120° C to achieve sufficient mechanical resistance for handling.

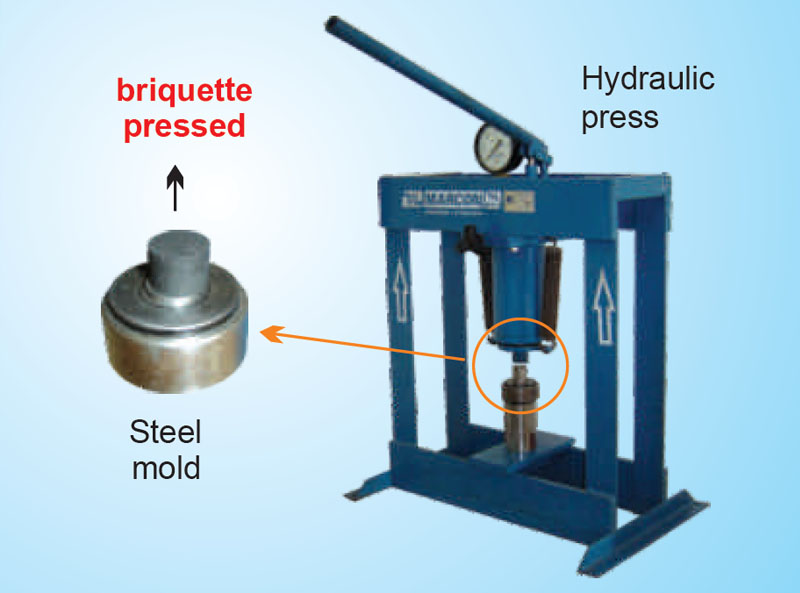

2. Briquetting

The residue (coke powder) was mixed with water and binders in WAM equipment to form a micro-granulated mass suitable for pressing. With the help of a small hydraulic press and steel mold, briquettes were formed with dimensions of 25 mm in diameter and 25 mm in height.

3. Extrusion

Utilizing a laboratory extruder and a paste mixed with water and binders, test bodies with dimensions of 25 mm in diameter and 50 mm in length were obtained through the WAM mixer.